Bug Check™ Bacteria and Fungi Tests are used in Various Industries

Our Bacteria Test Kits are used in various industries: E-coat, Metalworking Industry, Water Treatments, Oil & Gas, Coatings/Paints, Diesel Fuel Storage Tanks, Adhesives, Ink and many others.

______________________________________________________________________________

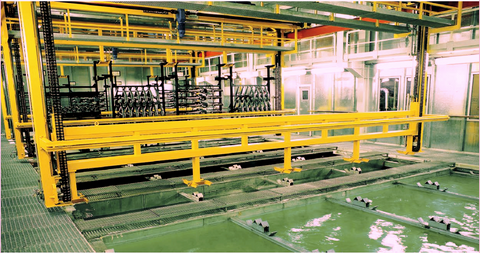

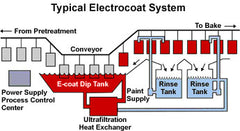

E-coat

E-coating system’s extensive use of water makes the process especially susceptible to microbial growth.

The water used in the e-coat process, (pre-painting and post-) creates a haven for bacteria to grow. Excess microbial growth can devastate the quality inherent in a well-run e-coat system.

Bug Check™ BF bacteria test kits enable non-scientists to monitor microbial levels right in a plant's e-coat system.

Bug Check™ BF dip-slides are easy-to-use and the most economical method of testing for bacteria on the factory floor. The test is intuitive, no user training is required, all supplies are included and no additional costly devices are needed.

All vendors of e-coating paint encourage bacteria testing.

______________________________________________________________________________

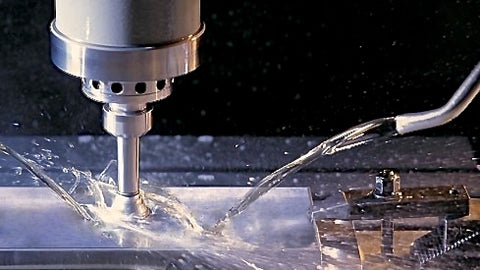

Metalworking Industry

Metalworking fluids and machine coolants make a perfect home for bacteria.

All that water, your lubricants (the food), and a little warmth, make an ideal nurturing environment for bacteria and mold growth.

Without regular microbial testing, often the first clue that there is a problem is the existence of a foul odor. Heavy microbial contamination can degrade fluids to a point where your expensive machine coolant can't be saved. Additionally, bacteria can result in the rusting of metal machining parts as well as being the cause of skin rashes on workers.

Typically, in a system with multiple sumps, 2 out of every 20 will be especially bad (strong bad odor) with an additional 4 sumps in need of treatment.

The advantage of regular monitoring and treatment of fluid is an increase in the fluid’s life by up to three times that of unmanaged fluids. Haul-off fees can then be drastically reduced in addition to the worries and concerns connected with disposal of spent fluids. These cost savings can be substantial, especially for the small effort required.

Monitoring consists of a few simple steps:

- Check the fluid suspended solids concentration daily using a refractometer: readings should be not too rich, nor too poor – generally a 5% solution of suspended solids.

- Daily inspections for tramp oil & trash. If present, remove.

- Weekly testing with Bug Check™ BF bacteria, fungi and mold test is where we come in. Try testing on a Friday and read the results the next Monday. If the microbial growth is >10^5, treat the sump.

(Similar to the three vital signs in the human body: heart rate, temperature, blood pressure)

Vital Indicator General Guidelines

- Suspended solids % 2% - 10% (target 5%)

- Microbial counts bacteria 105/ml; fungi 103/ml

- pH level 8.5 to 9.5

Haas Automation has included Bug Check™ BF in its cool YouTube video on coolant maintenance. This comprehensive video outlines in straight forward simple-to-follow terms how and why it pays to take care of your coolants.

Our bacteria test Bug Check™ BF makes a cameo appearance near the end of this informative film.

Take a look and learn.

Test kit for Metalworking fluids / Coolants / Cutting Fluids:

Coolant Additive for Metalworking fluids / Coolants / Cutting Fluids:

Sump Soda™ Ends Odor. Extends Coolant Life! Stops Bacteria! Prevents Health Issues!

______________________________________________________________________________

Oil & Gas Industry

Bacteria cause Corrosion in the oil and gas industry.

Microbes (or “bugs”) in the Oil and Gas Industry are the cause of microbial fouling of fracking fluids and of oil and gas wells, causing corrosion.This corrosion is often linked to the Sulfate Reducing Bacteria (SRB). The Bug Check™ SRB test kit is designed for on-site use and makes it easy to determine the extent of SRB contamination. For use on- and off-shore.

Test Kit for Fracking Fluids and Oil & Gas wells

Bacteria in the Oil Field

For an overview on bacteria in the oil field click on the link below:

Bacteria in the Oil Field

_______________________________________________________________________________

Fuel Storage:

Uncontrolled microbial contamination in hydrocarbon-based fluids such as fuels, and hydraulic fluids causes significant operational problems including corrosion, filter plugging and sludge formation. Bug Check™ FC is specifically designed for determining bacterial and fungal contamination levels in distillate fuels and similar low water content fluids.

Bacteria and Mold /Fungi Test Kit All Bacteria Test Kit

Questions? Call 847-446-9986 or email info@bugcheck.us

Stop the Stink with Sump Soda™

This coolant deodorizer is compatible with all major metalworking fluids: Castrol, DA Stuart, Fuchs, ChemTool, Quaker, Houghton, Master, AW Chesterton, DoAll, ITW Fluids, Milacron, Hangsterfer's & others.

Comparative active ingredient toTriadine™ and Triazine.

Sump Soda™ is a bacteria killer.

-

Sump Soda™ - 1 gallon jug; Use 1 qt/50 gal of coolant

Regular price $ 146.00Regular priceUnit price per -

Sump Soda™ - 5 gallon pail; Use 1 qt/50 gal of coolant

Regular price $ 517.00Regular priceUnit price per -

Sump Soda™ - 55 gallon drum; Use 1 qt/50 gal of coolant

Regular price $ 3,950.00Regular priceUnit price per

How Do I Determine When My Coolant is No Longer Safe?

The following signs indicate that a coolant is no longer safe to use and might be hazardous to workers health:

- Foul smell. Uncontrolled microbial growth causes metal working fluid to stink. It is important to address the cause of rancid smells, as the fine spray that is created during machining contains live microbes which can cause harmful health effects (dermatitis) in the employees who are exposed to this coolant mist. Foul smelling fluid is likely caused by microbial growth and needs to be analyzed and treated with biocide. Coolant that cannot be saved should be discarded appropriately. Before adding fresh coolant, the sump needs to be thoroughly cleaned.

- Abnormal fluid appearance. Check the color and appearance of the fluid regularly. Usually, synthetic fluids are clear, often the semi-synthetics appear transparent to milky, and soluble oil typically has a milky appearance with no oil layer. Bacteria often cause coolants to turn grey or black. Tramp oil may cause yellowing and browning of coolants. Colorless coolant is a sign of depleted coolant.

- Employees suffer from respiratory irritation. Exposure to coolant mist that is contaminated by bacteria and fungal spores can lead to irritation and tightness in the chest.